FROM MILL TO SEA: HOW YOUR AMERICAN-MADE CHAINS ARE MANUFACTURED

First Step - Heating

Each link begins as an alloy steel round bar purchased directly from an American steel mill. The bar is shot blasted and cut to size, before it’s moved down the line into the resistance heater. Clamps hold the bar in place while it is heated to over 1,600 degrees to prepare the bar for forming into a link

Second Step - Link Forming

The chain begins to take form as the heated steel is threaded through the previous link and hydraulically bent around a profiled mandrel, forming the next link.

Third Step - Welding

The formed link proceeds to the flash butt weld station. The combination of electric and hydraulic power produces a weld with a strength equivalent to the parent material.

Fourth Step - Trimming

The fourth station trims off any excess welding material, ensuring the new link arrives in your shipyard with a finished surface.

Fifth Step - Stud Pressing

When manufacturing stud link anchor chain, the center stud is pressed into the hot link and then welded in place if specified.

Sixth Step - Inspecting

You’re only as strong as your weakest link. To deliver the quality chain you require, we inspect each individual link. Both a visual and magnetic particle inspection on every weld is completed to confirm the integrity of each link.

Seventh Step - Heat Treating

The chain is then moved through two stages of heat treatment. Gas fired furnaces heat the chain to specific temperatures, before it’s water quenched and tempered to produce the strength and mechanical properties required to meet specifications.

Eighth Step - Testing

An on-site testing pit capable of exerting over 3 million pounds of load is used to guarantee the chain meets the specification’s strength requirements. Every link of chain is proof-tested before moving onto the final steps.

Ninth Step - Inspecting and Painting

The finished chain is visually and mag-particle inspected again before the paint coating is applied according to order instructions.

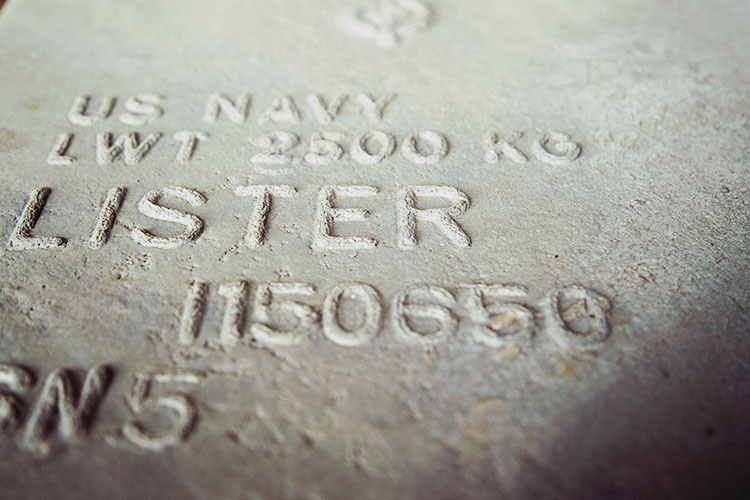

Tenth Step - Certifying

Every product leaves the factory with complete approval certification documents, fully traceable with a formal serial numbering process.